Sustainability

Toyota Motor Kyushu’s

Hydrogen Utilization Initiatives

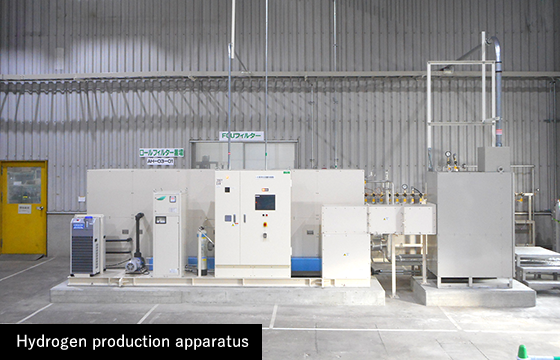

We are aiming for carbon neutrality at our factories by 2035 and are working toward comprehensively reducing factory CO2 emissions. Since 2017, we have been using green energy generated from solar power to produce hydrogen—clean energy that emits no CO2 when used. With this, we are operating a zero-CO2-emission process from production to use.

Initiatives for the expansion of hydrogen utilization

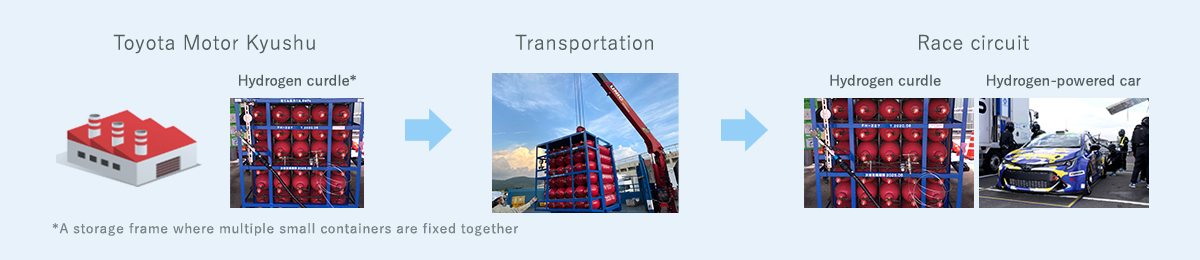

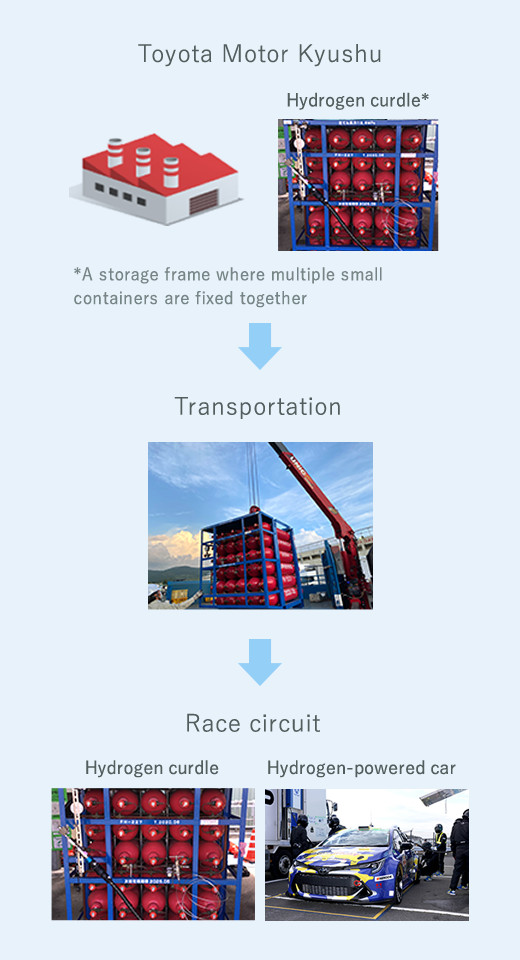

1) Supplying hydrogen in the Super Taikyu Series

At the 2021 Super Taikyu Series (circuits: Oita’s Autopolis and Okayama International Circuit), we supplied hydrogen produced using solar power at our factories to a hydrogen-powered car participating in the Series. We realized the hydrogen “production, transportation, and use” process together with local partners, and with this, we moved one step closer to achieving carbon neutrality in motorsports.

2) Future direction

We will collaborate with our external partners and attempt to develop new ways to utilize hydrogen.

- The high cost of production is the point most often addressed regarding hydrogen utilization. Accordingly, Toyota Motor Kyushu is conducting joint research with Kyushu University to reduce hydrogen production costs by extending the life of hydrogen facilities.

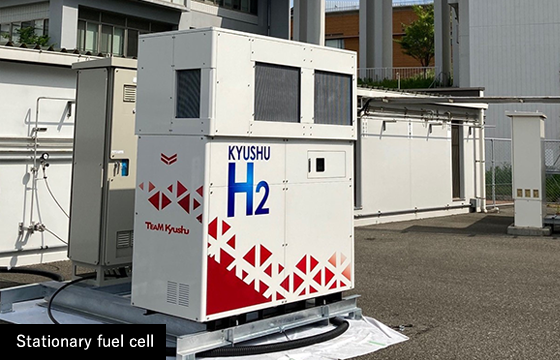

- Together with our external partners, we have started the development of stationary fuel cells and the demonstration of hydrogen-ready boilers .* While searching for new ways to utilize hydrogen, we are working on reducing CO2 emissions at our factories.

- *A boiler produces water vapor by heating water with natural gas. Hydrogen-ready boilers reduce the amount of natural gas used as they use a combination of natural gas and hydrogen, contributing to a reduction in CO2 emissions.